How fair can “Made in China” be?

-

With regional EU production, our products would cost over 200 euros due to lack of infrastructure.

-

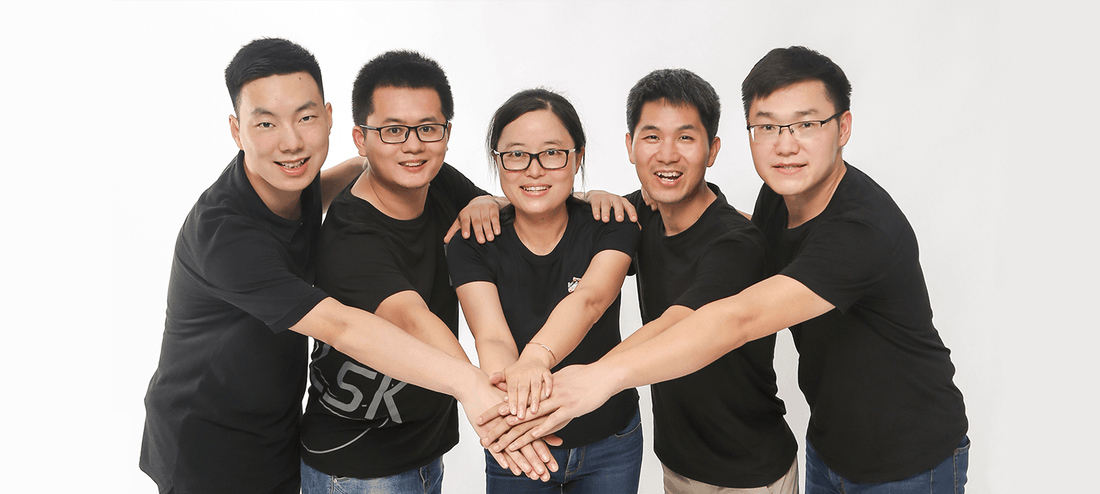

In Zhejiang, we have been working in partnership with our producers for years and have a 5-member FLSK team on site.

-

In the production facilities, we can guarantee fair working conditions such as minimum wage, free worker representation, and well-paid overtime.

Zhejiang - a versatile province in southeastern China. On the one hand, it is agriculturally shaped as the "Land of Fish and Rice." On the other hand, it is a global hub for stainless steel product manufacturing. And FLSK? Right in the middle!

German Production as a Pipe Dream

But why not Germany, at least Europe? Already in the early months of the company, the production issue was a pervasive topic. Endless inquiries and discussions followed. From the idea of converting adjacent industries like German mechanical engineering to the Polish-Czech production site. The sobering realization: regional production remains a pipe dream for now. The core issue with all variants is economic viability. We simply couldn't sell a bottle for over 200 euros.

China - the Stainless Steel Expert

Germany and large parts of Europe have been withdrawing from the manufacturing sector for many years. At the same time, the production of stainless steel products has increasingly shifted to Asia – among many other industries. Economic production in our latitudes? Impossible! The infrastructure has simply disappeared. In contrast, the Chinese region of Zhejiang has become increasingly professionalized. This is evidenced by the very short production routes. The entire production of the FLSK bottle and the FLSK coffee mug takes place within a 50-kilometer radius – from the steel sheet to the final packaging. Unthinkable in Germany! Also no secret: the even longer journey to Munich, which we do not ignore.

Far Away and Yet So Close

We are thousands of kilometers away from our suppliers in China. And a different culture. What does that mean for us? Creating closeness - as best as we can. Because we live fair cooperation in Munich and in Zhejiang. The basis for this is that we have been working on an equal footing with our suppliers since 2015. The focus is on joint development over years. We do not follow the local common practice of hunting for the cheapest provider but focus on long-term partnership. We achieve this through personal exchange, especially during Quentin's on-site visits several times a year. The second pillar is the 5-member FLSK China team, which we introduce to you here. Our production experts Mater, Xiaoli, Linda, Dave, and Hu (from left to right in the title image) visit our production sites daily for quality inspection. The image shows the FLSK China team during an on-site visit by Quentin.

What Exactly Does "Fair" Mean?

But quality for us does not only mean producing high-quality, durable products. Quality also includes the human component. We employ our 5-member FLSK China team directly with us. Here we pay equally to the colleagues in Munich. Additionally, we cover the social security benefits.

At our direct suppliers, external audits of the Business Social Compliance Initiative (BSCI) are conducted annually. This gives us an objective assessment of the working conditions in the factories. Most are rated as "good." The photo gallery below accompanies the production process of our main supplier.

What We Can Guarantee for All Our Direct Suppliers to Date:

- All employees are voluntarily contractually employed; there is no child or prison labor.

- In all companies, there are freely elected worker representations that meet regularly and can raise concerns.

- The pay of the factory workers corresponds to the regional minimum wage or is above it (our main producer pays 45% more).

- Overtime is worked exclusively voluntarily and compensated with a premium of 150% (weekdays) or 200% (weekends).

- All employees are provided with extensive protective equipment.

Our China Mission: Understanding Drives Us

What exactly "fair" means is always in the eye of the beholder. For us, it means encountering producers and employees on equal footing. We want to understand how they work and live there. Because the Chinese (work) culture is not the same as the German one. This means that some areas are handled differently. We have to accept that. One exemplary aspect that we encounter again and again: the issue of working hours. In China, the work ethic is generally high, and the overtime pay is very attractive. Consequently, many employees voluntarily work a lot of overtime.

Our part in this? Continuing to talk on equal terms about all relevant topics and understanding them – on both sides. And thus actively driving the process towards a joint understanding of "fairness."

- Engraveable.

FLSK coffee cup

500 ml · stainless - all natural

- Engraveable.

FLSK tumbler

500 ml · stone

- Engraveable.